How to Choose HVAC Systems for the Nuclear Power Industry

Choosing the right Heating, Ventilation, and Air Conditioning (HVAC) system for nuclear power plants is crucial for maintaining a controlled and safe environment. The HVAC system plays a critical role in managing temperature, humidity, air quality, and pressure within various sections of a nuclear facility, including reactor buildings, control rooms, and auxiliary buildings. Selecting the appropriate system involves several key considerations to ensure safety, reliability, and compliance with industry standards.

1. Safety and Compliance

Safety is the foremost concern in the nuclear power industry, and HVAC systems must meet strict regulatory standards and safety requirements. The system must be designed to:

- Comply with Nuclear Regulatory Commission (NRC) Standards: HVAC systems in nuclear power plants must adhere to NRC guidelines to ensure operational safety and control in the event of an emergency. This includes considerations for air filtration, pressure differentials, and safe operation under accident conditions.

- Meet ASME AG-1 Standards: The American Society of Mechanical Engineers (ASME) provides guidelines specific to HVAC systems for nuclear facilities. Compliance with ASME AG-1 is necessary for HVAC components that support safety-related functions.

- Seismic and Fire Resistance: HVAC systems in nuclear facilities must be able to withstand seismic events and fire conditions without losing operational capacity, as these are critical to maintaining safe operating environments during accidents or natural disasters.

2. Redundancy and Reliability

Reliability and redundancy are critical in nuclear HVAC systems to ensure that the system remains operational even in the event of a failure. This includes:

- Multiple Redundant Systems: HVAC systems should have backup components and systems in place to continue functioning if one part of the system fails. Redundant fans, filters, and cooling units are often required to ensure continuous operation.

- Fail-Safe Operation: The system must be designed to automatically transition to a fail-safe mode in the event of a power loss or system malfunction, ensuring that critical areas like the reactor building or control room maintain safe environmental conditions.

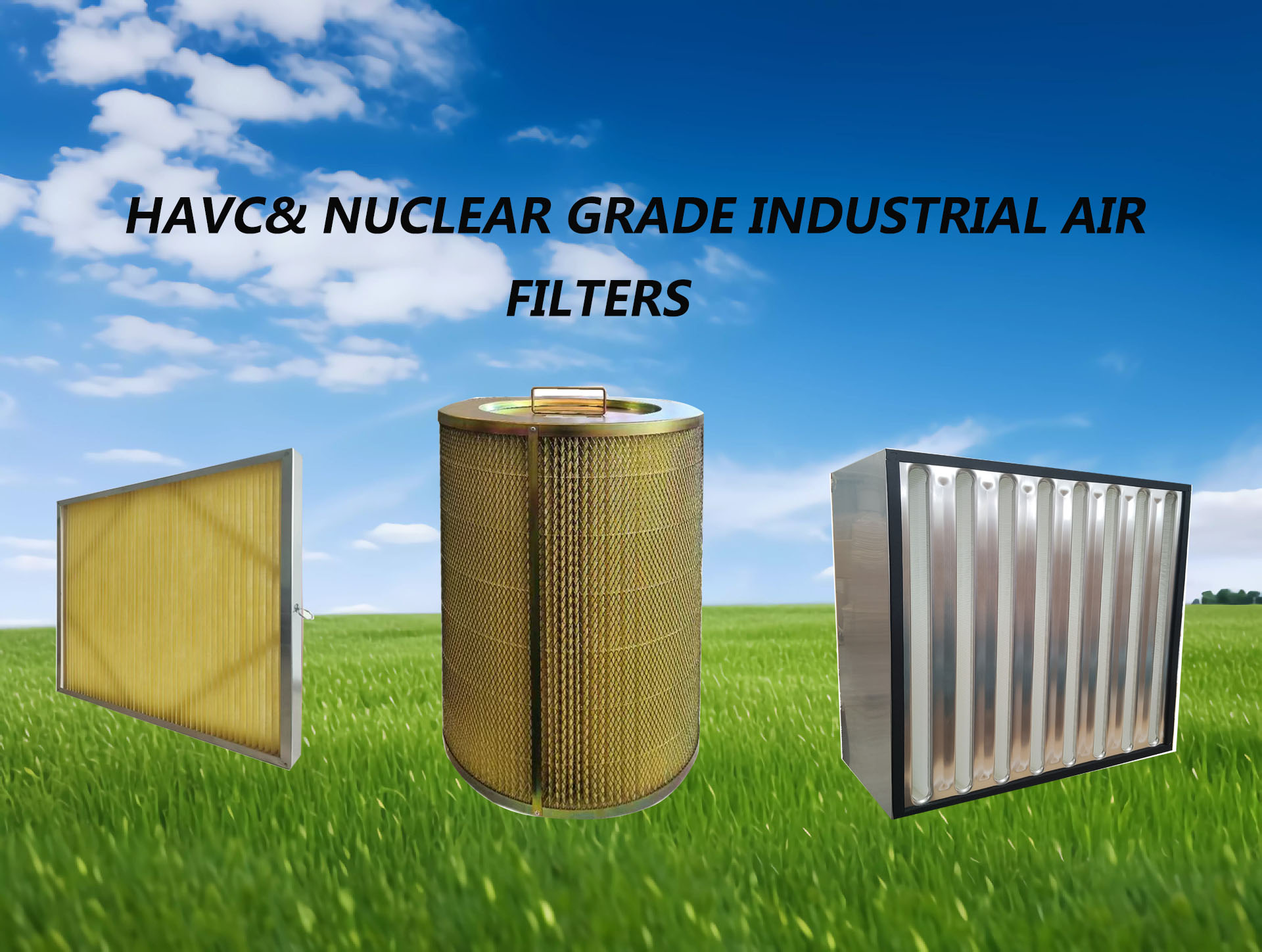

3. Contaminant Control and Air Filtration

Air quality is a vital factor in nuclear power plants, where radioactive contaminants may be present. HVAC systems must be designed to filter and control these contaminants effectively:

- High-Efficiency Particulate Air (HEPA) Filters: HEPA filters are essential for capturing airborne particles, including radioactive dust, ensuring clean air circulation throughout the facility. These filters typically have a minimum efficiency of 99.97% for particles as small as 0.3 microns.

- Charcoal Filters: Activated charcoal filters are often used to absorb radioactive iodine and other gaseous contaminants. These filters are critical in controlling the spread of radioactive gases, particularly during accidents or emergency scenarios.

- Pressurization and Zoning: The HVAC system must maintain specific pressure differentials between zones to control the flow of air and prevent contaminants from spreading. Clean areas like the control room should be positively pressurized relative to contaminated zones.

4. Temperature and Humidity Control

Maintaining a stable temperature and humidity level is critical for both the comfort of personnel and the optimal functioning of sensitive equipment in a nuclear plant:

- Precise Climate Control: Temperature fluctuations can affect the performance of critical equipment such as control panels, electrical systems, and cooling systems. The HVAC system must provide precise and consistent climate control to prevent malfunctions caused by overheating or excessive moisture.

- Humidity Regulation: Humidity control is important in preventing corrosion, condensation, and other issues that could damage sensitive equipment. HVAC systems should be designed to maintain appropriate humidity levels within the plant’s various zones.

5. Energy Efficiency

Although energy efficiency is a consideration in any industrial HVAC system, it is particularly important in nuclear facilities where operational efficiency and cost-effectiveness are crucial. Some energy-saving strategies include:

- Variable Air Volume (VAV) Systems: These systems adjust airflow based on demand, reducing energy consumption during low-load periods. VAV systems can help nuclear facilities maintain comfortable environments while minimizing energy waste.

- Energy Recovery Ventilation (ERV): ERV systems capture energy from exhaust air and use it to precondition incoming air, reducing the need for additional heating or cooling. This enhances the overall efficiency of the HVAC system.

- Advanced Monitoring Systems: Integrating smart monitoring systems can optimize HVAC operation by providing real-time data on temperature, humidity, and airflow, ensuring efficient use of resources and minimizing downtime.

6. Corrosion and Durability

Given the harsh operating environment in nuclear power plants, HVAC components must be built to withstand corrosion, wear, and exposure to radioactive materials:

- Corrosion-Resistant Materials: HVAC systems should be constructed from materials that resist corrosion, particularly in areas exposed to steam, chemicals, or radiation. Stainless steel, for instance, is often used for ductwork and filtration housing to prevent degradation over time.

- Radiation-Resistant Components: In areas exposed to radiation, the HVAC system should include components that can withstand the effects of radiation without breaking down or compromising performance.

7. Maintenance and Accessibility

Nuclear facilities operate 24/7, and HVAC systems must be easy to maintain without causing disruptions to operations. Considerations for maintenance include:

- Modular Components: HVAC systems designed with modular components allow for easier repairs and replacements without the need for extensive downtime. This is especially important for parts like filters and fans that need regular replacement.

- Remote Monitoring and Diagnostics: Advanced monitoring systems that provide real-time diagnostic data allow operators to detect and address potential issues before they lead to system failure. This reduces the risk of downtime and ensures the HVAC system remains operational.

8. Emergency Ventilation Systems

Nuclear power plants must have robust emergency ventilation systems in place to handle extreme situations like nuclear accidents, fires, or equipment malfunctions:

- Safety Ventilation Systems: These systems are designed to manage airflows during emergency situations, ensuring that hazardous contaminants are contained and that clean air is supplied to critical areas like the control room.

- Filtered Containment Ventilation Systems: In the event of an accident, these systems ensure that any radioactive gases are filtered before being released into the environment, thereby protecting both plant personnel and the surrounding community.

Conclusion

Selecting the right HVAC system for a nuclear power plant requires careful consideration of safety, reliability, contaminant control, energy efficiency, and compliance with regulatory standards. By choosing a system that meets the specific demands of a nuclear environment, facilities can maintain safe air quality, protect critical equipment, and ensure smooth operation under both normal and emergency conditions.