How to Choose Industrial Air Filters

Selecting the right industrial air filter is critical for ensuring air quality, protecting machinery, and maintaining worker safety in industrial settings. The type of filter needed depends on various factors such as the environment, the type of pollutants, and the desired level of filtration. Here’s a guide on how to choose the most appropriate industrial air filter for your needs.

1. Understand the Type of Contaminants

The first step in choosing an industrial air filter is to identify the types of contaminants you need to filter out. Common contaminants include:

- Dust and Particulates: These are common in industries like woodworking, metalworking, and construction.

- Chemical Vapors and Fumes: Found in industries that involve painting, welding, or chemical processing.

- Oil Mist: Common in machining operations where oils or coolants are used.

- Biological Pollutants: In industries like food processing or pharmaceuticals, air filters may be required to eliminate bacteria, mold, and other biological contaminants.

Knowing the specific type of pollutants in your facility helps in selecting the right filter with the proper filtration capability.

2. Choose the Appropriate Filtration Technology

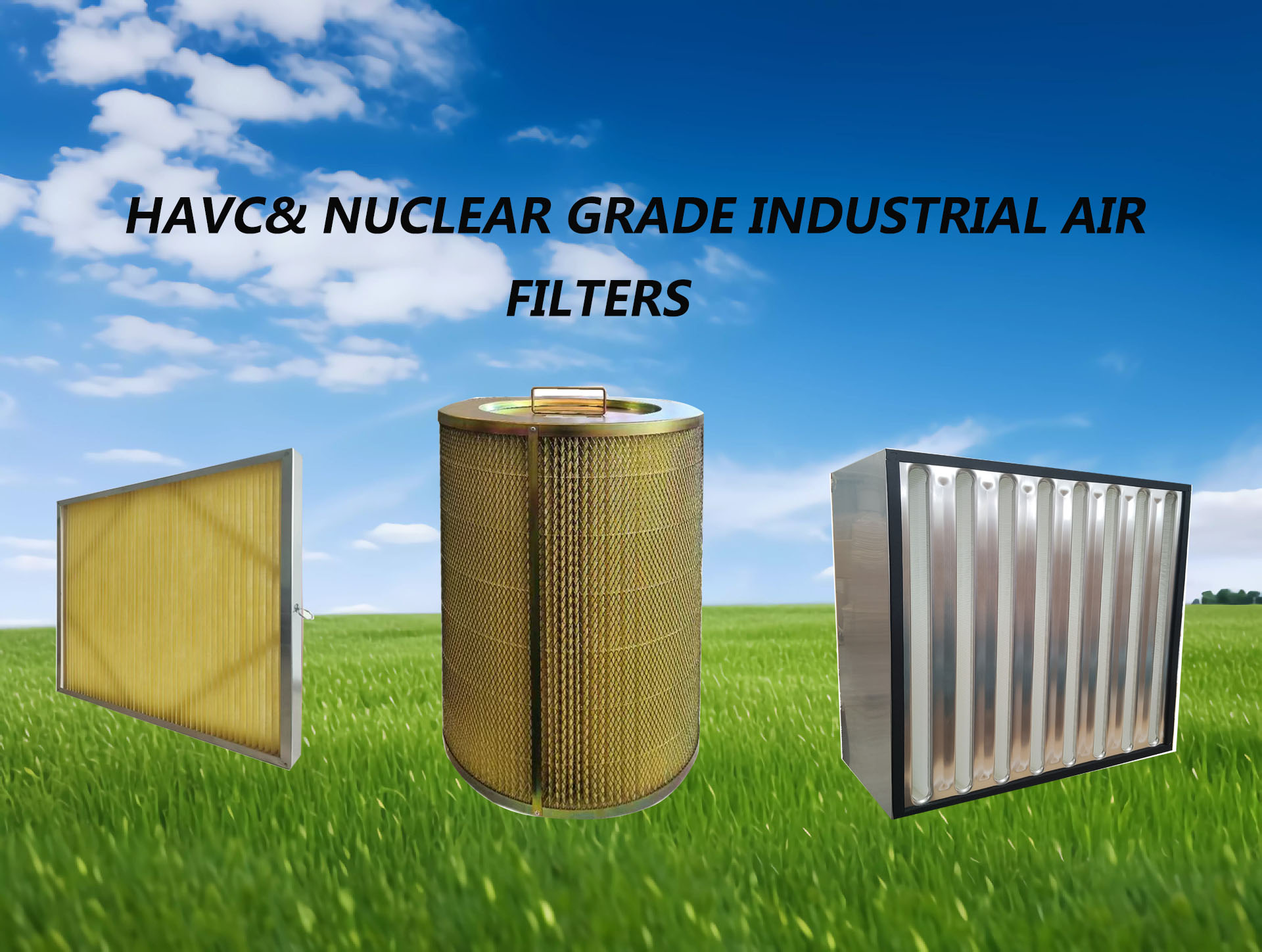

Industrial air filters come in different types, depending on the filtration method used. Some common types include:

- Mechanical Filters: These capture particles through a physical barrier. Examples include HEPA (High-Efficiency Particulate Air) filters, which are ideal for removing fine dust and airborne particulates.

- Electrostatic Filters: These use electrical charges to attract and trap particles. They are effective in removing smoke, dust, and fine particulates.

- Activated Carbon Filters: These are ideal for removing gases, odors, and chemical vapors from the air. Activated carbon is highly porous and adsorbs volatile organic compounds (VOCs).

- Oil Mist Filters: Specifically designed for industries like metalworking, these filters capture oil mist and coolant particulates generated during machining processes.

Each technology is suited for specific applications, so understanding your filtration needs will help narrow down the options.

3. Consider Filtration Efficiency

The filtration efficiency of an air filter indicates how effectively it removes contaminants from the air. It is commonly measured by the Minimum Efficiency Reporting Value (MERV) scale, HEPA ratings, or efficiency percentages:

- MERV Rating: Filters with a MERV rating of 1 to 16 are used to capture particles of various sizes. A higher MERV rating indicates better filtration performance, particularly for smaller particles. Industrial applications often require MERV ratings of 13 or higher.

- HEPA Filters: HEPA filters are highly efficient, capturing 99.97% of particles as small as 0.3 microns, making them ideal for industries requiring high levels of air purity.

- ULPA Filters: Ultra-Low Penetration Air (ULPA) filters capture even smaller particles, around 0.1 microns, and are used in environments requiring extremely clean air, such as laboratories.

Depending on the type of contaminants and the level of filtration required, choose a filter with the appropriate efficiency rating.

4. Airflow Requirements

Another critical factor to consider is the airflow capacity of the filter. The filter must handle the volume of air passing through it without creating excessive resistance, which can lead to inefficient filtration or equipment failure. Check the airflow rate (measured in cubic feet per minute, or CFM) to ensure the filter can meet the demands of your industrial processes.

- Pressure Drop: A low-pressure drop across the filter ensures smooth airflow and reduces energy consumption.

- Fan Capacity: Ensure that your ventilation system’s fan is capable of supporting the filter without causing strain or reducing air circulation efficiency.

5. Durability and Maintenance

In industrial settings, filters are often exposed to harsh environments and require frequent maintenance. When choosing a filter, consider the following:

- Material Durability: The filter should be made of materials that can withstand the specific industrial environment, whether it’s high temperatures, humidity, or chemical exposure.

- Maintenance Requirements: Some filters are reusable and can be cleaned, while others are disposable. Reusable filters may reduce long-term costs but may require regular cleaning. Disposable filters, on the other hand, may be more convenient but involve ongoing replacement costs.

- Filter Replacement Frequency: Choose a filter that balances durability with ease of replacement, especially in environments where regular maintenance may not be feasible.

6. Size and Compatibility

Ensure the filter is the correct size and compatible with your existing filtration system or industrial machinery. Filters that are too small or too large will not function properly and could lead to inefficiencies or equipment damage.

- Custom Sizing: In some cases, you may need custom-sized filters to fit specific equipment or industrial setups.

- Compatibility with Equipment: Ensure that the filter works well with your existing HVAC or ventilation systems, taking into account airflow, pressure, and mounting requirements.

7. Compliance with Industry Standards

Certain industries have specific regulations and standards regarding air filtration. Ensure that the filter you select complies with relevant regulations such as:

- OSHA Standards: Occupational Safety and Health Administration (OSHA) standards often dictate air quality requirements in industrial workplaces.

- ISO Standards: Depending on the industry, filters may need to meet ISO standards for cleanrooms, particularly in manufacturing and healthcare sectors.

- Local Environmental Regulations: Certain regions may have environmental laws regarding emissions and air quality, particularly in industries that release harmful pollutants.

8. Cost and Budget Considerations

While it may be tempting to choose the cheapest option, investing in a high-quality filter can reduce long-term maintenance costs and downtime caused by poor air quality. Consider:

- Initial Cost vs. Long-Term Savings: While a more expensive filter may have a higher upfront cost, its efficiency and durability could save you money in the long run.

- Energy Efficiency: Filters with lower pressure drops often use less energy, reducing operational costs. Energy-efficient filters may have a higher initial cost but can lead to savings on energy bills.

Conclusion

Choosing the right industrial air filter requires a clear understanding of the specific pollutants in your facility, the desired level of filtration, and the requirements of your industrial environment. By selecting a filter with the appropriate filtration technology, efficiency, durability, and compatibility, you can ensure cleaner air, improved worker safety, and the long-term performance of your equipment.